|

Performance Steps

|

|

1. Clear the MK19.

|

a.

Place the safe/fire switch

in the SAFE (S) position. Ensure the

bolt is forward.

|

b.

Open the top cover and

inspect the feed tray and extractors

on the bolt face to ensure that no

round is in the pickup position.

|

c.

Unlock and pull charger

handle 2 to 3 inches to the rear;

inspect the face of the bolt and the

chamber for ammunition.

|

d.

Return the bolt to the

forward position and rotate the

charger handle to the locked position.

|

|

2. Disassemble the MK19.

|

a.

Remove the feed throat

assembly (figure 071-030-0001-1).

Squeeze the two sets of grip pins

together and pull them straight out.

|

b.

Remove the bolt and

backplate assembly.

|

|

Figure 071-030-0001-1.

Removal of feed throat assembly

|

|

WARNING:

Make sure the

bolt is in the forward position

before you remove the backplate pin

assembly. Failure to observe this

warning will result in injury.

|

(1)

Place the safe/fire switch

on FIRE (F).

|

(2)

Open the top cover.

|

(3)

Using the rim of a spent

cartridge, pull the backplate pin

straight out (figure 071-030-0001-2).

|

|

Figure 071-030-0001-2.

Removal of backplate pin

|

(4)

Lift up slightly on the

backplate assembly. Slowly pull the

bolt and backplate assembly out of the

receiver.

|

(5)

Support the bolt with one

hand and maintain a control grip with

the other hand. Lift the bolt up

slightly and remove it (figure 071-030-0001-3).

|

|

Figure 071-030-0001-3.

Removal of bolt and backplate assembly

|

c.

Remove the primary drive

lever and vertical cam assembly.

|

|

CAUTION:

Do not rest the

vertical cam assembly on its chromed

surface.

|

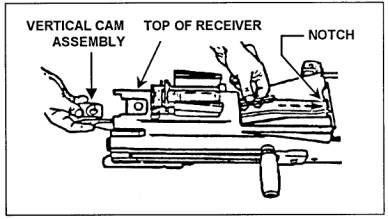

(1)

Reach under the top of the

receiver to locate the drive lever

lock on the vertical cam assembly and

slide the lock rearward about 1/4 inch

(figure 071-030-0001-4).

|

|

Figure 071-030-0001-4.

Primary drive lever and vertical cam

assembly

|

(2)

Press down on the primary

drive lever’s pivot post. This

releases the primary drive lever and

vertical cam assembly (figure 071-030-0001-5).

|

|

Figure 071-030-0001-5. Removal of the primary drive lever

and vertical cam assembly

|

(3)

Pull out the cam (to the

rear) and the lever from the receiver.

|

d.

Remove secondary drive

lever.

|

(1)

Push down on the pivot post

from the outside top cover. This

releases the secondary drive lever

(figure 071-030-0001-6).

|

|

Figure 071-030-0001-6.

Removal of the secondary drive lever

|

(2)

Lift out the secondary

drive lever from the top cover (figure 071-030-0001‑7).

|

|

Figure 071-030-0001-7.

Secondary drive lever.

|

e.

Remove the feed slide

assembly (Figure 071-030-0001-8).

|

|

Figure 071-030-0001-8.

Removal of the feed slide assembly.

|

(1)

Pivot the tray that holds

the feed slide assembly out of the top

cover.

|

(2)

Move the feed slide

assembly to line up the tabs with the

slots in the tray.

|

(3)

Lift upward on the feed

slide assembly.

|

f.

Remove the top cover

assembly and feed tray (figure 071-030-0001-9).

|

|

Figure 071-030-0001-9.

Removal of the top cover assembly and

feed tray

|

|

CAUTION:

Using your

fingers only, not pliers, remove the

top cover pins. Forcing the pin

could break the small cross pin on

the rod.

|

|

Note. The feed tray must be down for you to remove the top

cover pins.

|

(1)

Hold the top cover straight

up to align the end of the cross pin.

|

(2)

Pull straight out on the

pins.

|

(3)

Lift off the top cover.

|

(4)

Lift the tray out of the

feeder.

|

g.

Remove the alignment guide

assembly (figure 071-030-0001-10).

|

|

Figure 071-030-0001-10.

Removal of the alignment guide assembly

|

(1)

Depress the flat leaf

spring by using a cartridge link

toggle (male end) or a small tool.

|

(2)

Slide the alignment guide

toward the feeder mouth.

|

(3)

Pull rearward on the

alignment guide and lift it out.

|

h.

Remove the ogive plunger by

pulling it out (figure 071-030-0001-11).

|

|

Figure 071-030-0001-11.

Removal of the ogive plunger

|

i.

Remove the round

positioning block (figure 071-030-0001-12).

|

|

Figure 071-030-0001-12.

Removal of the round positioning block

|

(1)

Grasp the two control grips

with both hands and lift up slightly

to disengage the backplate from the

locking lugs in the receiver.

|

(2)

Pull the round positioning

block toward the muzzle end of gun.

|

j.

Remove the charger

assemblies (both sides) (figure 071-030-0001-13).

|

|

Figure 071-030-0001-13.

Removal of the charger assembly

|

(1)

Rotate the charger handle

up.

|

(2)

Using either your fingers

or a spent case, pry out on the lip of

the lock plunger.

|

(3)

Lift up on the lock plunger

to retract it; slide the charger

assembly all the way to the rear.

|

(4)

Pull the charger assembly

away from the receiver.

|

k.

Remove the receiver sear

assembly (figure 071-030-0001-14).

|

|

Figure 071-030-0001-14.

Removal of the receiver sear assembly

|

(1)

Turn the receiver on its

top. Put the safe/fire switch in FIRE

(F) position.

|

(2)

Lift up slightly on the

lock pin with your fingers, using a

cartridge link.

|

(3)

Squeeze the receiver sear

(underneath the safety) and

simultaneously rotate the sear housing

assembly approximately 15 degrees in

either direction.

|

(4)

Press down on the sear

housing assembly and rotate the

assembly until it stops (90 degrees

from its original position).

|

(5)

Press the receiver sear and

safety together while you put

safe/fire switch on safe (S). This

locks the sear in the down position

and keeps you from accidentally losing

the sear spring.

|

(6)

Lift out the sear housing

assembly.

|

|

3. Clean the parts of the MK19.

|

|

Note. Do not reverse the direction of the bore brush while it

is in the bore.

|

a.

Clean the receiver assembly

(figure 071-030-0001-15).

|

|

Figure 071-030-0001-15.

Receiver assembly

|

(1)

Apply solvent to a rag or

brush. Wipe or brush dirt away from

all parts, especially the interior of

the receiver housing, receiver rails,

and feeder.

|

(2)

Swab out the bore and

chamber, using a bore brush and RBC.

|

(3)

Wipe all parts dry.

|

b.

Clean the receiver sear

assembly (figure 071-030-0001-14).

|

(1)

Use only cleaning solvent

on a rag or brush.

|

(2)

Wipe or brush away dirt.

|

(3)

Wipe dry.

|

|

WARNING:

Never immerse

the sear housing assembly in

solvent. Solvent may dilute the

lubricant inside the sear housing.

|

c.

Clean the alignment guide

assembly, ogive plunger, round

positioning block, and secondary drive

lever; wipe or brush off dirt and dry.

|

|

WARNING:

Never immerse

the ogive plunger assembly in

solvent.

|

d.

Clean the charger

assemblies.

|

(1)

Apply cleaning solvent to a

rag or brush, and wipe or brush off

dirt.

|

(2)

Wipe dry.

|

e.

Clean the vertical cam

assembly, primary drive lever, feed

slide assembly, and feed tray.

|

(1)

Soak in cleaning solvent.

|

(2)

Wipe or brush off dirt.

|

(3)

Wipe dry.

|

f.

Clean the top cover

assembly.

|

(1)

Apply cleaning solvent to a

rag or brush and wipe or brush off

dirt from all parts.

|

(2)

Wipe all surfaces dry.

|

g.

Clean the bolt and

backplate assembly.

|

(1)

Apply cleaning solvent to

rag or brush and wipe or brush off

dirt from all parts.

|

(2)

Wipe all surfaces dry.

|

|

4. Clean the components.

|

a.

Clean the T&E

mechanism.

|

(1)

Remove foreign matter with

a clean, dry wiping rag.

|

(2)

Use small arms cleaning

brush to clean the numbers on the

scale.

|

b.

Clean the M3 tripod, MK64

gun cradle mount, and pintle.

|

(1)

Use a cleaning swab

saturated with carbon removing

compound to remove dirt.

|

(2)

Wipe all parts dry with

clean wiping rags.

|

|

5. Clean ammunition. Remove foreign matter with a

clean, dry wiping rag.

|

|

6. Inspect all MK19 parts for serviceability.

|

a.

Receiver assembly.

|

(1)

Check the receiver housing

for cracks and rust.

|

(2)

Check the receiver rails

for burrs and cracked welds.

|

(3)

Check the feeder pawls for

burrs and lack of spring action. Check

the pins for retention.

|

(4)

Check the barrel for carbon

buildup and pitting in the bore and

chamber.

|

(5)

Check the flash suppressor

for dents, cracks, and erosion. Make

sure minimal movement is maintained.

|

(6)

Check the rear sight for

rust, binding, and broken or bent

parts.

|

b.

Receiver sear assembly.

|

(1)

Check for burrs on all

parts.

|

(2)

Closely inspect the rear

shoulder for burrs.

|

c.

Alignment guide assembly.

|

(1)

Check the alignment guide

spring for deformity, cracks, and

looseness.

|

(2)

Check the pin for breaks

and cracks.

|

d.

Ogive plunger assembly and

round positioning block.

|

(1)

Check the ogive plunger

head for burrs and broken parts.

|

(2)

Check the round positioning

block for weak spring action and loose

or broken parts.

|

e.

Charger assembly (left and

right).

|

(1)

Check the grooved edges for

burrs and bends.

|

(2)

Check the latches for

spring action on detects.

|

(3)

Check the entire charger

assembly for cracks, burrs, bends, and

chips.

|

f.

Vertical cam assembly and

primary drive lever.

|

(1)

Check the vertical cam

assembly for bends, burrs, pits,

scratches, and aluminum buildup on

chromed surface (mirror-like surface).

|

(2)

Check the drive lever lock

for looseness or binding.

|

(3)

Check the primary drive

lever for burrs, especially around the

pivot posts.

|

g.

Secondary drive lever.

|

(1)

Check for missing retaining

ring from the pivot post.

|

(2)

Check the pivot post and

forked end for burrs.

|

h.

Feed slide assembly and

feed tray.

|

(1)

Check the feed pawls and

feed tray for burrs and binding.

|

(2)

Check the guide rails for

burrs.

|

i.

Top cover assembly.

|

(1)

Check the top cover housing

for cracks and rust.

|

(2)

Check the latch for

binding, looseness, and breaks.

|

j.

Bolt and backplate

assembly.

|

(1)

Check the cocking lever for

chips, burrs, and breaks.

|

(2)

Check the guide rods for

binding and bends.

|

(3)

Check the recoil spring for

weak action. Position the bolt end

against a hard, flat surface and push

up and down on backplate assembly.

|

(4)

Check the backplate pin for

missing retaining spring.

|

(5)

Check for missing, loose or

broken safety wire.

|

k.

Report any deficiencies to

supervisor.

|

|

7. Inspect all components for serviceability.

|

a.

T&E mechanism.

|

(1)

Inspect the hand wheels for

smooth operation and rust. Check the

threads for burrs and rust.

|

(2)

Check the traversing slide

lock for spring action. Make sure the

elevating mechanism sleeve fits on the

traversing bar and clamps firmly.

|

(3)

Check the traversing and

elevating scales for legibility.

|

(4)

Inspect the quick release

pin and chain for burrs and rust;

check for missing spring-loaded balls.

|

b.

M3 Tripod.

|

(1)

Check for completeness of

tripod; make sure all nuts and bolts

are tightly secured.

|

(2)

Check for cracks on the

legs and tripod head.

|

(3)

Check for missing, broken,

or inoperative lock latch.

|

(4)

Check the pintle lock

release cam for correct operation.

|

(5)

Check the locking action of

the front leg clamping assembly.

|

(6)

Make sure the rear legs

lock in the open position, the sleeve

latch notch and the right leg slide

notch engage completely, and the latch

spring has good tension.

|

(7)

Check the telescoping,

indexing, and locking actions of rear

legs and front leg locking assembly.

|

c.

MK64 gun cradle mount.

|

(1)

Check for missing or

damaged parts.

|

(2)

Check for rust, cracks, and

burrs.

|

(3)

Inspect pintle lock

assembly for nut, bolt, and cotter

pin. Check the pintle surface for

burrs and rust.

|

d.

Report any deficiencies to

supervisor.

|

|

8. Inspect ammunition for damage and corrosion. Turn

in any unserviceable ammunition.

|

|

9. Lubricate the MK19 and components. Do not use CLP,

and do not mix lubricants.

|

|

CAUTION:

1. Never immerse

the sear housing, ogive plunger, or

bolt assemblies in cleaning solvent.

Solvent could dilute the lubricant

or grease inside.

2. Never

lubricate the MK19 with CLP.

3. Avoid mixing

lubricants.

4. Completely

wipe off all excess lubricants.

|

a.

Lubricate lightly to

moderately with LSAT, LSA, or GMD

(never CLP). In cold weather (0 to -25

degrees Fahrenheit), use LSAT, LSA,

GMD, or LAW. In extra cold weather

(-25 degrees Fahrenheit and below),

use LAW.

|

b.

Apply lubricant to all

weapon parts and surfaces except

charger handles. Work in the lubricant

by moving the parts.

|

c.

Lubricate all components

and wipe them with an oily rag to

remove excess oil.

|

|

10. Assemble the MK19 machine gun.

|

a.

Attach the charger

assemblies (both sides) (figure 071-030-0001-16).

|

|

Figure 071-030-0001-16.

Attachment of the charger assemblies

|

(1)

Turn the receiver upright.

|

(2)

Rotate the charger handles

to the straight-up position.

|

(3)

Line up the lugs on the

charger with the slots in the receiver

rail. Insert the charger lugs into the

slots.

|

(4)

Hold the charger tightly

against the rail. Slide the charger

forward until it locks into place.

|

b.

Attach the round

positioning block (Figure 071-030-0001-17).

|

|

Figure 071-030-0001-17.

Attachment of the round positioning

block

|

(1)

Insert the blocks into the

slots with the tang end forward.

|

(2)

Push against the block and

slide it toward the rear until the

block locks into place.

|

c.

Insert the ogive plunger

assembly into the opening.

|

d.

Insert the alignment guide

assembly (figure 071-030-0001-18).

|

|

Figure 071-030-0001-18.

Insertion of the alignment guide

assembly

|

(1)

Position the alignment

guide assembly so the pin is lined up

with the slot in the feeder wall.

|

(2)

Hold the alignment guide

against the front wall and slide the

alignment guide into the receiver

until it clicks.

|

e.

Attach the feed tray and

feed slide assembly (figure 071-030-0001-19).

|

|

Figure 071-030-0001-19.

Attachment of the feed slide assembly

|

(1)

Place the tray in the top

of the feeder, recessed side up.

|

(2)

The pinholes on the tray

should line up with the lugs on the

receiver.

|

(3)

Position the feed slide

assembly by lining up the tabs with

the slots on the tray.

|

(4)

Insert the tabs into the

slots. Drop the feed slide assembly

into the tray and move it slightly to

ensure engagement.

|

f.

Attach the top cover

assembly (figure 071-030-0001-20).

|

|

Figure 071-030-0001-20.

Attachment of the top cover assembly

|

(1)

Ensure the feed tray is in

the proper place in the receiver.

|

(2)

Place the top cover on the

receiver. Line up the pinholes on the

cover with the receiver’s lug end and

the pinholes on the feed tray.

|

(3)

Hold the top cover straight

up. Insert the top cover pins on both

sides. Fully insert the cross pin.

Rotate the top cover so it is fully

open.

|

|

WARNING:

To avoid

breaking the cross pin, be sure to

insert it fully into the receiver

before you close the top cover.

|

g.

Engage the secondary drive

lever (figure 071-030-0001-21).

|

|

Figure 071-030-0001-21.

Engaging the secondary drive lever

|

(1)

Rotate the feed slide

assembly and tray upward.

|

(2)

Engage the forked end of

the secondary drive lever with the

feed slide pin.

|

(3)

Press the raised pivot post

through the hole in the stop cover.

|

(4)

Press the secondary drive

lever against the top cover until it

locks into place.

|

|

CAUTION:

Be sure to engage

the secondary drive lever with the

feed slide pin, or the gun will not

fire.

|

|

h.

Engage the vertical cam

assembly (figure 071-030-0001-22).

|

|

Figure 071-030-0001-22.

Engaging the vertical cam assembly.

|

(1)

Slide the vertical cam

assembly through the rear of the

receiver. The raised portion should

slide over the top of the receiver.

The drive lever lock should be

underneath.

|

(2)

Engage the forked end in

the notch.

|

i.

Engage the primary lever

(figure 071-030-0001-23).

|

|

Figure 071-030-0001-23.

Engaging the primary drive lever

|

(1)

Hold the vertical cam

assembly in place and slide the

primary drive lever into the receiver.

|

(2)

Slide the primary drive

lever lock to the rear and engage the

pivot post lever through the holes in

the receiver and vertical cam.

|

(3)

Slide the primary drive

lever lock forward. (The primary drive

lever lock is located on the vertical

cam just beneath the top of the

receiver).

|

j.

Insert the bolt and

backplate assembly (figure 071-030-0001-24).

|

|

Figure 071-030-0001-24.

Insertion of the bolt and backplate

assembly

|

(1)

Place the safe/fire switch

in the fire (F) position.

|

(2)

Press the receiver sear

using your thumbs or the rim of a

cartridge case.

|

(3)

Make sure the cocking lever

is cocked and forward.

|

(4)

Slide the bolt and

backplate assembly all the way

forward.

|

(5)

Insert the backplate pin to

lock the assembly in place.

|

(6)

Close the cover.

|

|

WARNING:

Before

inserting the bolt and backplate

assembly, put the cocking lever in

the forward position.

|

|

CAUTION:

Before closing

the top cover, always make sure the

secondary drive lever engages the

feed slide pin, the feed slide

assembly is to the left, and the

bolt is forward. Never try to force

the top cover closed. Doing so could

damage the weapon.

|

k.

Attach the receiver sear

assembly (figure 071-030-0001-25).

|

|

figure 071-030-0001-25. Attachment of the receiver sear

assembly

|

(1)

Turn the receiver over on

its top.

|

(2)

Place the sear housing on

the receiver and line up the sear

housing assembly at a right angle to

the barrel center line.

|

(3)

Put the safe/fire switch on

fire (F) position.

|

(4)

Press down and rotate the

housing assembly until it stops.

|

(5)

Press up on the sear and

rotate it until it locks in position.

|

l.

Attach the feed throat

assembly.

|

(1)

Squeeze the grip pins and

align them with the holes in the

receiver.

|

(2)

Release the grip pins to

attach the feed throat.

|

|

11. Perform a function check to make sure you have assembled the

weapon correctly.

|