|

Performance Steps

|

|

1. Clear the caliber .50 machine gun.

|

a.

Unlock the bolt latch

release and raise the cover (figure 071-022-0001-1).

|

b.

Pull and lock the bolt to

the rear, leaving the retracting slide

handle to the rear.

|

c.

Inspect the chamber and

T-slot to make sure they hold no

rounds.

|

d.

Place a wooden block inside

the receiver, between the bolt and the

rear of the barrel.

|

e.

Insert the cleaning rod in

the muzzle end of the barrel until you

can see the rod in the receiver.

Remove the cleaning rod.

|

f.

Grasp the retracting slide

handle, press the bolt latch release,

and ease the bolt forward. Close the

cover.

|

|

Figure 071-022-0001-1.

Raising the cover

|

|

2. Disassemble the machine gun.

|

a.

Remove the barrel assembly.

|

(1)

Raise the cover group

(figure 071-022-0001-1).

|

(2)

Grasp the retracting slide

handle with the right hand, palm up.

Pull the bolt to the rear until the

barrel locking spring lug aligns with

the 3/8-inch hole in the right side

plate of the receiver (figure 071-022-0001-2).

|

(3)

Place the smallest loop of

a caliber .50 link between the

trunnion block and the barrel

extension (figure 071-022-0001-2).

This keeps the barrel locking spring

lug aligned with the 3/8-inch hole.

|

(4)

Unscrew the barrel from the

receiver. Be careful not to damage the

threads or barrel locking notches.

|

(5)

Remove the caliber .50 link

to allow the bolt to go forward

slowly. Make sure the bolt group does

not slam forward with the barrel

removed.

|

|

Figure 071-022-0001-2.

Alignment of the lug

|

b.

Remove the backplate

assembly.

|

|

WARNING:

Do not remove

the backplate unless the bolt is in

the forward position. When removing

the backplate, stand to one side of

the weapon to avoid possible injury

from the driving spring rod.

|

(1)

Ensure that the bolt is

forward and the bolt latch release is

unlocked (in the single shot mode)

(figure 071-022-0001-3).

|

|

Figure 071-022-0001-3.

Releasing the bolt latch

|

(2)

Pull the backplate latch

lock straight back while lifting up on

the backplate latch (figure 071-022-0001-4).

|

|

Figure 071-022-0001-4.

Removal of the backplate

|

(3)

Remove the backplate

assembly by lifting straight up.

|

c.

Remove the driving spring

rod assembly (figure 071-022-0001-5).

|

|

Figure 071-022-0001-5.

Removal of the driving spring rod

assembly

|

(1)

Push the rear of the

driving rod assembly forward and to

the left to free it from the side of

the receiver.

|

|

WARNING:

Never try to

charge the machine gun while the

backplate is off and the driving

spring rod assembly is in place. If

the backplate is off and the driving

spring assembly is compressed, the

retaining pin on the driving spring

can slip from its seat in the side

plate. This could cause serious

injury to anyone behind the machine

gun.

|

(2)

Pull the driving spring rod

assembly to the rear and out of the

receiver.

|

d.

Remove the bolt assembly.

|

(1)

Retract the bolt assembly

far enough to the rear to align the

bolt stud with the bolt stud hole in

the right side plate of the receiver

(figure 071-022-0001-6).

|

|

Figure 071-022-0001-6.

Removal of the bolt stud

|

(2)

If you accidentally move

the bolt all the way to the rear, the

bolt latch will engage in the bolt

latch notches in the top of the bolt.

If this occurs, raise the bolt latch

and push the bolt forward to align the

bolt stud with the clearance hole

(figure 071-022-0001-7).

|

|

Figure 071-022-0001-7.

Unlatching the bolt

|

(3)

Remove the bolt stud.

|

(4)

Remove the bolt assembly by

pulling it from the rear of the

receiver (figure 071-022-0001-8).

|

|

Figure 071-022-0001-8.

Removal of the bolt from the receiver

|

(5)

Disassemble the bolt.

|

(a)

Rotate the cartridge

extractor upward and remove it from

the left side of the bolt (figure 071-022-0001-9).

|

|

Figure 071-022-0001-9.

Removal of the cartridge extractor and

bolt

|

(b)

Remove the bolt switch by

lifting it straight up.

|

(c)

Place the cocking lever in

its rearmost position. Press down on

the sear with a swab holder and

release the firing pin spring (figure 071-022-0001-10).

|

|

Figure 071-022-0001-10.

Releasing the firing pin spring

|

(d)

Insert a swab holder

section in the hole at the rear of the

bolt and push out the cocking lever

pin and the cocking lever (figure 071-022-0001-11).

|

|

Figure 071-022-0001-11.

Removal of the cocking lever pin and

cocking lever

|

(e)

Use the thin end of the

cocking lever to rotate the

accelerator stop lock to the center of

the bolt, then pry up the accelerator

stop lock and remove it (figure 071-022-0001-12).

|

|

Figure 071-022-0001-12.

Removal of the accelerator stop lock

|

(f)

Using the thin end of the

cocking lever, press the accelerator

stop from the bolt, turn the bolt

over, and pry the accelerator stop

from bottom of bolt (figure 071-022-0001-13).

|

|

Figure 071-022-0001-13.

Removal of the accelerator stop

|

(g)

Depress the sear and remove

the sear slide, sear, and sear spring

(figure 071-022-0001-14).

|

|

Figure 071-022-0001-14.

Removal of the sear slide, sear, and sear spring

|

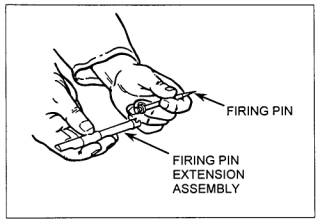

(h)

Tip the front end of the

bolt upward and remove the firing pin

extension assembly (figure 071-022-0001-15).

|

|

Figure 071-022-0001-15.

Removal of the firing pin extension

assembly

|

(i)

Remove the firing pin from

the firing pin extension assembly.

|

e.

Remove the barrel buffer

and barrel extension assemblies

(figure 071-022-0001-16).

|

|

Figure 071-022-0001-16.

Removal of the barrel buffer group and

barrel extension group

|

(1)

Insert a pointed instrument

(you can use the pointed end of the M4

cleaning rod) in the hole at the lower

rear corner of the right side plate.

Depress the buffer body lock and, at

the same time, place one hand inside

the receiver and push the barrel

extension and buffer assemblies to the

rear until the buffer accelerator is

near the rear of the receiver body.

|

|

WARNING:

Maintain

thumb pressure on the buffer

accelerator while removing the

barrel buffer and barrel extension

assemblies.

|

(2)

Maintain pressure on the

buffer accelerator with your thumb and

remove the barrel buffer and barrel

extension assemblies from the

receiver. Separate them by pushing

forward on the accelerator tips

(figure 071-022-0001-17).

|

|

Figure 071-022-0001-17.

Separation of the barrel buffer and

barrel extension assemblies.

|

(3)

Disassemble the barrel

buffer assembly.

|

(a)

Remove the buffer assembly

by pushing it out the rear of the body

of the barrel buffer (figure 071-022-0001-18).

|

|

Figure 071-022-0001-18.

Removal of the barrel buffer assembly

|

(b)

Using a swab holder, drive

the accelerator pin assembly from the

barrel buffer body group.

|

(c)

Remove the buffer

accelerator.

|

(4)

Disassemble barrel

extension assembly.

|

(a)

Using the pointed end of

the M4 cleaning rod, remove breech

lock pin assembly (figure 071-022-0001-19).

|

|

Figure 071-022-0001-19.

Removal of

the breech lock pin assembly and

breech lock

|

(b)

Remove breech lock.

|

f.

Disassemble receiver

assembly.

|

(1)

Remove the front cartridge

stop and rear cartridge stop assembly

(figure 071-022-0001-20).

|

|

Figure 071-022-0001-20.

Removal of the cartridge stop

assemblies

|

(2)

Press down on belt holding

pawl assembly to prevent loss of

springs, and remove the belt holding

pawl pin. Remove belt holding pawl

assembly and springs (figure 071-022-0001-21).

|

|

Figure 071-022-0001-21.

Removal of the belt holding pawl pin,

assembly, and springs

|

(3)

Raise the loop of the

trigger lever pin and rotate it into a

vertical position. Reach inside the

receiver, grasp the trigger lever, and

remove the trigger pin assembly and

trigger lever (figure 071-022-0001-22).

|

|

Figure 071-022-0001-22.

Removal of the trigger lever pin

assembly and trigger lever

|

|

3. Clean the .50 caliber machine gun and components.

|

a.

Barrel assembly.

|

(1)

Clean the bore. Screw the

bore brush into the cleaning rod, dip

the bore brush in RBC, and push the

cleaning rod through the chamber end

of barrel. Unscrew the bore brush from

the cleaning rod. Repeat the process

until clean.

|

(2)

Clean the chamber. Screw

the chamber brush into the cleaning

rod, dip the chamber brush in RBC, and

clean the chamber using a clockwise

twisting motion.

|

(3)

Insert a cleaning swab in

the cleaning rod and swab out the bore

from the chamber end and back. Repeat

until a swab comes out clean.

|

(4)

Wipe outside surfaces of

barrel with carbon removing compound.

|

(5)

Remove all traces of RBC

before lubricating.

|

|

Note. Do not submerge the backplate assembly in any fluid.

|

b.

Backplate assembly. Use

only clean wiping rags to remove

foreign matter from backplate.

|

c.

Bolt assembly. Clean all

parts of bolt assembly with a cleaning

swab saturated with carbon removing

compound. Clean the face of the bolt

with a cleaning swab soaked in RBC.

|

d.

Clean barrel buffer

assembly, barrel extension assembly,

and receiver assembly with a cleaning

swab saturated with carbon removing

compound. Wipe all parts dry with

clean wiping rags.

|

e.

Clean components.

|

(1)

T&E mechanism.

Remove foreign matter with a

clean dry wiping rag.

Use a small arms cleaning brush

to clean numbers on the scale.

|

(2)

Clean M3 tripod, MK64 gun

cradle mount, and pintle with a

cleaning swab saturated with carbon

removing compound.

Wipe all parts dry with clean

wiping rags.

|

f.

Ammunition. Remove foreign matter with a clean dry wiping rag.

|

|

4. Inspect for serviceability.

|

a.

Barrel assembly.

|

(1)

Check barrel locking

notches for wear.

|

(2)

Check the bore for bulges,

missing bands, and large pits.

|

b.

Backplate assembly.

|

(1)

Check guides for burrs and

bends.

|

(2)

Check backplate latch and

backplate lock for proper functioning.

|

(3)

Make sure locking pins are

in place.

|

(4)

Check trigger and bolt

latch release for proper functioning.

|

(5)

Make sure handle grips do

not move freely and are not cracked.

|

c.

Driving rod assembly.

|

(1)

Check for flat spots on

springs.

|

(2)

Make sure springs operate

freely and rod and pin are not bent.

|

d.

Bolt assembly.

|

(1)

Check movement of cartridge

extractor in bolt; it should raise and

lower without binding. Check movement of cartridge ejector.

|

(2)

Check bolt switch, cocking

lever pin, cocking lever, accelerator

stop lock, accelerator stop, and sear

slide for cracks, bends, and burrs.

|

(3)

Inspect sear for cracks and

burrs.

Inspect sear notch for wear,

chips, and burrs.

Inspect sear spring for breaks

and lack of tension.

|

(4)

Inspect firing pin for

cracks and chipped or sharp tip.

Tip should be smooth and well

rounded.

|

(5)

Check firing pin extension

for cracks, burrs, and free movement

in bolt.

|

(6)

Make sure bolt is free of

burrs and cracks and firing pin hole

is not visually out of round.

|

e.

Barrel buffer assembly.

|

(1)

Inspect buffer body lock

for tension, staking, and retention in

barrel buffer body.

|

(2)

Inspect buffer accelerator

for broken claws or chipped tips.

|

(3)

Inspect accelerator pin

assembly for broken or missing spring.

|

(4)

Inspect buffer spring for

cracks or breaks.

|

(5)

Inspect breech lock

depressors.

They must have slight vertical

(up and down) movement but should have

no lateral (side to side) movement.

|

f.

Barrel extension assembly.

|

(1)

Make sure barrel extension

assembly is not bent and the bolt

guideways are smooth and free of

burrs.

|

(2)

Inspect threads of barrel

extension assembly for damage.

|

(3)

Make sure barrel locking

spring is staked and fully seated in

its groove.

Also, make sure the locking end

of the spring has good tension and the

lug is not damaged.

|

(4)

Check breechblock for

smooth movement in guideways of barrel

extension assembly.

|

g.

Receiver and cover

assembly.

|

(1)

Inspect belt holding pawl

brackets for looseness, bends, and

cracks.

|

(2)

Inspect side plates for

bends that would affect movement of

any internal parts.

|

(3)

Check for cracks and burrs

at backplate grooves.

|

(4)

Check operation of rear

sight.

Make sure windage and elevation

screws function properly, leaf

assembly has good spring tension, and

sight assembly is secured tightly to

receiver.

|

(5)

Make sure bolt stop is

present and in good condition.

|

(6)

Make sure trigger lever

moves freely.

|

(7)

Make sure trigger lever pin

locks in place.

|

(8)

Make sure cotter pin is in

place on extractor switch.

|

(9)

Check retracting slide

assembly for visible damage.

Check retracting slide handles

for smooth movement.

Make sure cotter pins are

present and in good condition, and

safety wire is in place and properly

laced.

|

h.

Inspect components.

|

(1)

T&E mechanism.

|

(a)

Inspect hand wheels and

threads for burrs and rust.

Check hand wheels for smooth

operation.

|

(b)

Make sure traversing slide

lock lever has spring action.

Make sure elevating mechanism

sleeve fits on traversing bar and

clamps firmly.

|

(c)

Check traversing and

elevating scales for legibility.

|

(d)

Inspect quick release pin

and chain for burrs and rust.

Check quick release pin for

presence of spring loaded balls.

|

(2)

M3 tripod.

|

(a)

Check for completeness of

tripod.

Make sure all nuts and bolts

are tightly secured.

|

(b)

Check for visible cracks on

legs and tripod head.

|

(c)

Check for missing, broken,

or inoperative sleeve lock latch.

|

(d)

Check pintle lock assembly.

Check surfaces of pintle, bolt,

and nut for burrs and rust.

Make sure cotter pin is present

and in good condition.

|

(e)

Check locking action of

front leg clamping assembly.

|

(f)

Check that rear legs lock

in the open position.

Make sure sleeve latch notch

and right leg slide notch engage

completely. Make sure latch spring has good tension.

|

(g)

Check telescoping,

indexing, and locking action of rear

legs and front leg clamping assembly.

|

(3)

MK64 gun cradle mount.

|

(a)

Check for missing or

damaged parts.

|

(b)

Check for rust, cracks, and

burrs.

|

(c)

Check pintle lock assembly.

Check surfaces of pintle, bolt,

and nut for burrs and rust.

Make sure cotter pin is present

and in good condition.

|

i.

Inspect ammunition.

Check for damage or corroded

rounds.

|

|

5. Lubricate the .50 caliber machine gun.

|

a.

Remove all traces of RBC or

carbon removing compound.

|

|

CAUTION:

Do not mix

lubricants on the same weapon.

The weapon must be thoroughly

cleaned with dry cleaning solvent

during change from one lubricant to

another.

|

b.

Lubricate exterior of

backplate with a light coat of oil.

Do not lubricate interior of

backplate.

|

c.

Lubricate all other parts

with a light coat of LSA or CLP (at

temperatures above 0 degrees

Fahrenheit) or LAW (at temperatures

below 0 degrees Fahrenheit).

|

|

6. Assemble the .50 caliber machine gun.

|

a.

Assemble the trigger lever

(Figure 071-022-0001-23).

|

|

Figure 071-022-0001-23.

Assembly of the trigger lever

|

(1)

Place the trigger lever bar

in the receiver directly under the

timing nut so the hole in the trigger

lever bar is aligned with the mounting

hole in the receiver.

|

(2)

Insert trigger lever pin

assembly (loop end vertical) in the

assembly hole on left side of

receiver.

Match key on trigger lever pin

with keyway in side plate of receiver

and install the pin completely.

|

(3)

Rotate trigger pin lever

assembly 90 degrees and lock in place.

Fold the loop end down.

|

b.

Assemble receiver group.

|

(1)

Determine the direction of

feed.

Figure 071-022-0001-24

shows left-hand feed.

Place the right-hand rear

cartridge stop assembly and front

cartridge stop on the belt holding

pawl bracket.

|

|

Figure 071-022-0001-24.

Installation of the rear cartridge

stop assembly and front cartridge stop

|

(2)

Install belt holding pawl

pin with hooked end to rear.

|

(3)

Seat belt holding pawl

springs in place on the belt holding

pawl bracket.

|

(4)

Place belt holding pawl

assembly on the springs.

Compress springs and insert

belt holding pawl pin (figure 071-022-0001-25).

|

|

Figure 071-022-0001-25.

Installation of the belt holding pawl

assembly

|

c.

Assemble barrel extension

(figure 071-022-0001-26).

|

|

Figure 071-022-0001-26.

Assembly of the barrel extension assembly

|

(1)

Install breechblock lock

with beveled edge up and to the front

of barrel extension assembly.

|

(2)

Install breech lock pin

assembly in barrel extension.

Make sure both ends of breech

lock pin assembly are flush with sides

of barrel extension assembly.

|

d.

Assemble barrel buffer

assembly.

|

(1)

Place buffer accelerator

(tips up) into barrel buffer body,

align mounting holes, and install

buffer pin assembly.

Ensure both ends of barrel

buffer pin assembly are flush with

sides of barrel buffer body (figure 071-022-0001-27).

|

|

Figure 071-022-0001-27. Assembly

of the barrel buffer assembly

|

(2)

Align key on barrel buffer

assembly with key slot in barrel

buffer body and slide barrel buffer

assembly into barrel buffer body.

|

(3)

Hold the barrel buffer

assembly with the buffer accelerator

up and engage the notch on the shank

of the barrel extension assembly with

the cross groove in the piston rod of

the barrel assembly (figure 071-022-0001-28).

|

|

Figure 071-022-0001-28.

Attachment of the barrel buffer and barrel extension assemblies

|

(4)

Align breech lock

depressors in grooves of barrel

extension assembly and push barrel

buffer assembly forward.

|

(5)

Install barrel buffer

assembly and barrel extension assembly

in receiver (figure 071-022-0001-29).

|

|

Figure 071-022-0001-29.

Installation of the barrel buffer and barrel extension assemblies

|

e.

Assemble bolt assembly.

|

(1)

Attach firing pin to firing

pin extension assembly (figure 071-022-0001-30).

|

|

Figure 071-022-0001-30.

Attachment of the firing pin to the firing pin extension assembly

|

(2)

Insert firing pin extension

assembly into bolt with notch of

firing pin extension assembly down

(Figure 071-022-0001-31).

|

|

Figure 071-022-0001-31.

Installation of the firing pin

extension assembly

|

(3)

Slide firing pin extension

assembly forward so tip of firing pin

protrudes from face of bolt.

|

(4)

Place sear spring in recess

on bolt.

Slide sear down into vertical

grooves at rear of bolt with

wedge-shaped lug pointed outward and

upward (figure 071-022-0001-32).

|

|

Figure 071-022-0001-32.

Installation of the sear side

|

(5)

Compress sear spring by

pressing down on the sear.

Install sear slide from left

side of bolt in grooves of bolt with

"V" notch down.

|

|

Note. Make sure

the pin end of the accelerator is

installed behind the firing pin

spring, not through a coil.

|

(6)

Insert pin end of

accelerator stop through bottom of

bolt (figure 071-022-0001-33).

|

|

Figure 071-022-0001-33.

Attachment of the accelerator stop

|

|

Note. Base end of

accelerator stop should be installed

with long end forward so beveled edges

match.

|

(7)

Turn bolt over.

Place forked end of accelerator

stop lock on notched end of

accelerator stop.

|

(8)

Using the wedge-shaped end

of the cocking lever, press down on

the flat end of the accelerator stop

lock, and move the cocking lever into

the groove on the left side of the

bolt (figure 071-022-0001-34).

|

|

Figure 071-022-0001-34.

Attachment of the accelerator stop

lock

|

(9)

Insert cocking lever, with

rounded nose on lower end of lever to

rear, into slot in top of bolt (figure

071-022-0001-35).

|

|

Figure 071-022-0001-35.

Attachment of the cocking lever

|

(10)

Align the hole in the

cocking lever with the holes in the

bolt.

Insert the cocking lever pin

from the left side.

|

(11)

Push the cocking lever

forward to charge the firing pin.

Return the cocking lever to the

rearward position.

|

|

WARNING:

Do not try to

release the firing pin with the

cocking lever forward.

The cocking lever could

spring back forcibly and cause

serious injury.

|

(12)

Test firing pin release.

Trip the firing pin by

depressing the top of the sear with a

section of a swab-holder.

If doing so makes a sharp

metallic sound, the firing pin spring

is in good condition (figure 071-022-0001-36).

|

|

Figure 071-022-0001-36. Testing the firing pin release

|

(13)

Place cocking lever in forward

position.

Determine the direction of feed

before installing the bolt switch.

|

(14)

Place bolt switch in

position so the feed groove is

continuous for feed direction

indicated (figure 071-022-0001-37).

|

|

Figure 071-022-0001-37.

Setting the bolt switch

|

(15)

Hold cartridge extractor in

vertical position and insert shank end

of cartridge extractor into left side

of bolt.

Make sure cartridge extractor

fits into bolt as far as possible.

|

(16)

Rotate cartridge extractor

downward to full horizontal position.

Check that flange on bottom of

cartridge extractor has engaged

shoulder on bolt.

|

(17)

Ensure cocking lever is

forward.

|

(18)

Push bolt assembly forward

into receiver until bolt latch engages

notches in top of bolt assembly

(figure 071-022-0001-38).

|

|

Figure 071-022-0001-38.

Installation of the bolt assembly

|

(19)

If you cannot install the

bolt this way, remove the barrel

extension and buffer assembly from the

receiver.

Install the bolt assembly into

the barrel extension and buffer

assembly, then install them in the

receiver (figure 071-022-0001-39).

|

|

Figure 071-022-0001-39.

Installation of the bolt assembly

within the barrel extension and buffer assembly

|

(20)

Raise bolt latch and push

bolt assembly into the receiver.

|

(21)

Align holes in bolt

assembly with stud assembly hole in

receiver and install bolt stud in hole

in bolt assembly.

Place bolt in forward position

(figure 071-022-0001-40).

|

|

Figure 071-022-0001-40. Installation of the bolt assembly

|

f.

Assemble driving spring rod

assembly (figure 071-022-0001-41).

Install the driving spring rod

assembly in the upper right corner of

the bolt.

Push forward and to the right

until the driving spring rod assembly

engages in the hole in the side plate

of the receiver-not in the groove

for the backplate.

|

|

Figure 071-022-0001-41. Installation of the driving spring

rod assembly

|

g.

Install backplate assembly

(figure 071-022-0001-42).

|

|

Figure 071-022-0001-42.

Installation of the backplate assembly

|

(1)

Align backplate assembly

with receiver grooves.

Pull backplate latch lock while

lifting up on backplate latch.

Lower backplate assembly down

until engaged in receiver.

|

(2)

Test proper locking by

pulling up on backplate assembly.

|

h.

Assemble barrel assembly.

|

(1)

Retract bolt far enough for

barrel locking spring lug to center in

barrel locking spring hole on right

side of receiver.

|

(2)

Place the smallest loop of

a caliber .50 link between the

trunnion block and the barrel

extension.

This holds the barrel locking

spring lug aligned with the 3/8-inch

hole.

|

(3)

Install and screw barrel

assembly completely into receiver.

Unscrew barrel assembly two

clicks and check headspace.

|

|

7. Perform a function check to make sure weapon is

assembled correctly.

|

a.

Place the weapon in the

single-shot mode.

|

b.

Open the cover and pull the

retracting slide handle to the rear.

Bolt should lock to rear in

single-shot mode.

|

c.

Hold the retracting slide

handle to the rear; depress bolt latch

release and ease the bolt forward.

|

d.

Press trigger; weapon

should fire.

|

e.

Place the weapon in the

automatic-fire mode.

|

f.

Pull the retracting slide

handle to the rear and hold.

Bolt should not lock to rear in

automatic-fire mode.

|

g.

Release pressure on the

retracting slide handle and ease the

bolt forward.

|

h.

Press trigger; weapon

should fire.

|